Faucet production process

Production process of faucet are as follow:

Copper ingot-->Dissolution-casting (low-grade casting with sand casting, high-quality faucet with

gravity casting)-->Casting cleaning-->Casting inspection-->CNC machining (including shape peeling, dilling and tapping)-->tolerance inspection --> Leakage-->Grinding (also known as grinding and shiny polishing) --> Surface inspection -->Electroplating

-->Electroplating inspection -->Assembly --> Water leak test -->Finished product inspection -->Packaging -->Delivery.

Casting: low-grade casting with sand casting, high-quality faucet with gravity casting, the new technology is die-casting, and the

primary grinding is similar to the current zinc alloy die-casting process.

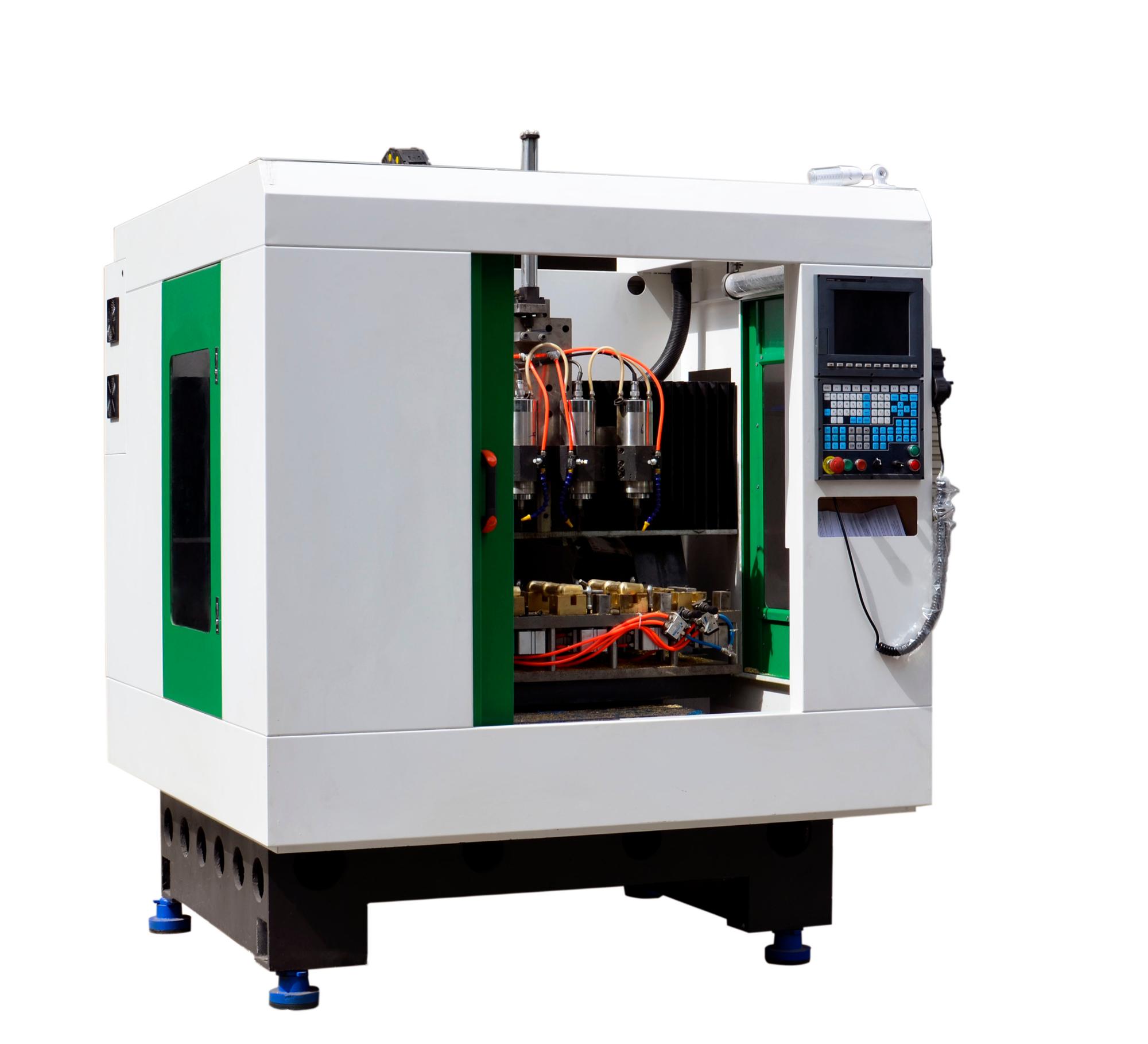

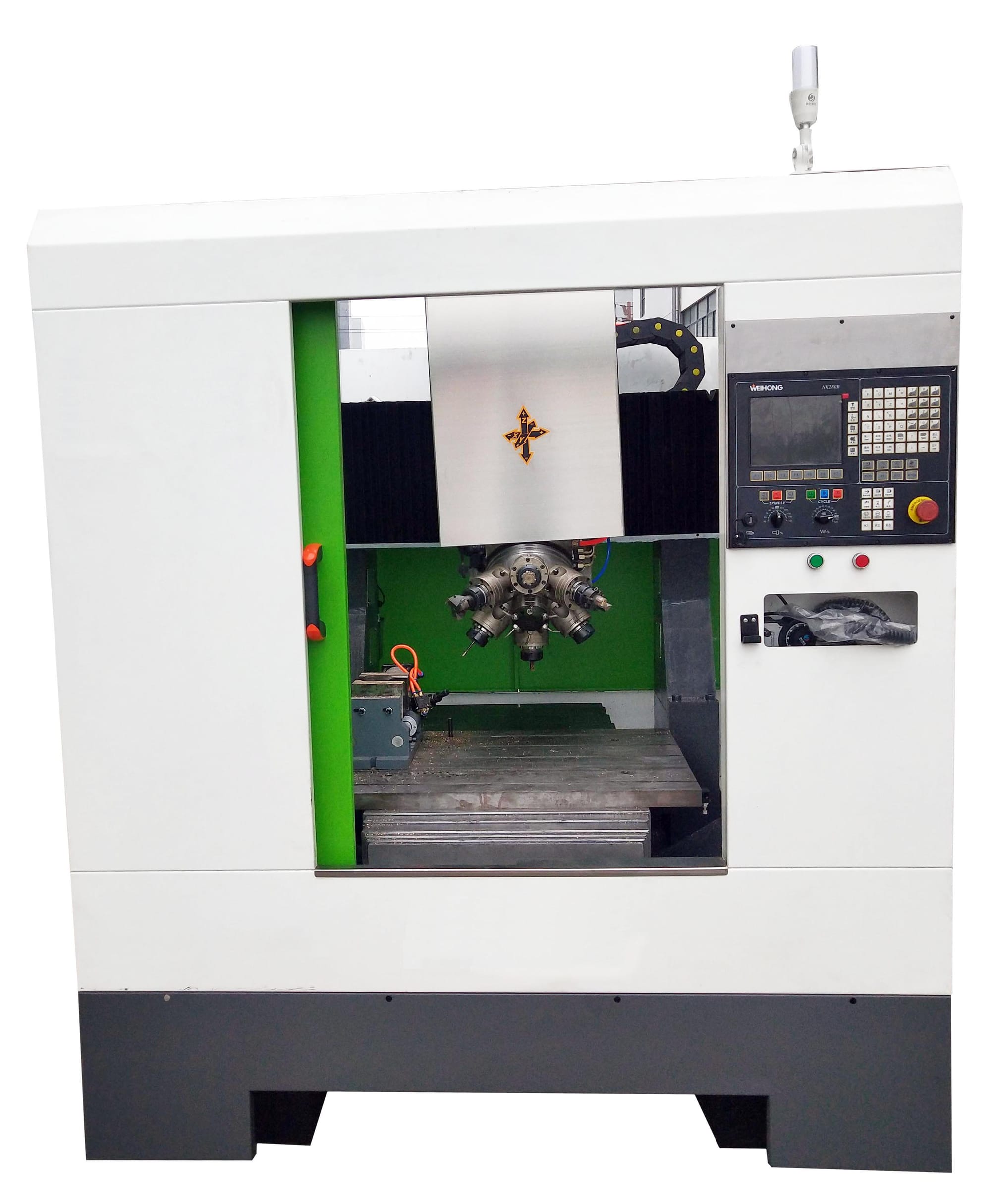

Shentuautomation innovated economic and high-efficiency faucet CNC machining machinery: faucet peeling machine, crown type turret tapping machine center QB860.

Our 8-spindle faucet peeling machine can finish grinding 200 faucets or metal mold in 8 hours and each can be precisely in the same shape! the chips can be 99% recycled at high price.

QB860 travel is 800*600mm, it can take the place of light duty VMC850, but the cost is 40% lower than VMC850. it is an amazing faucet making machine.

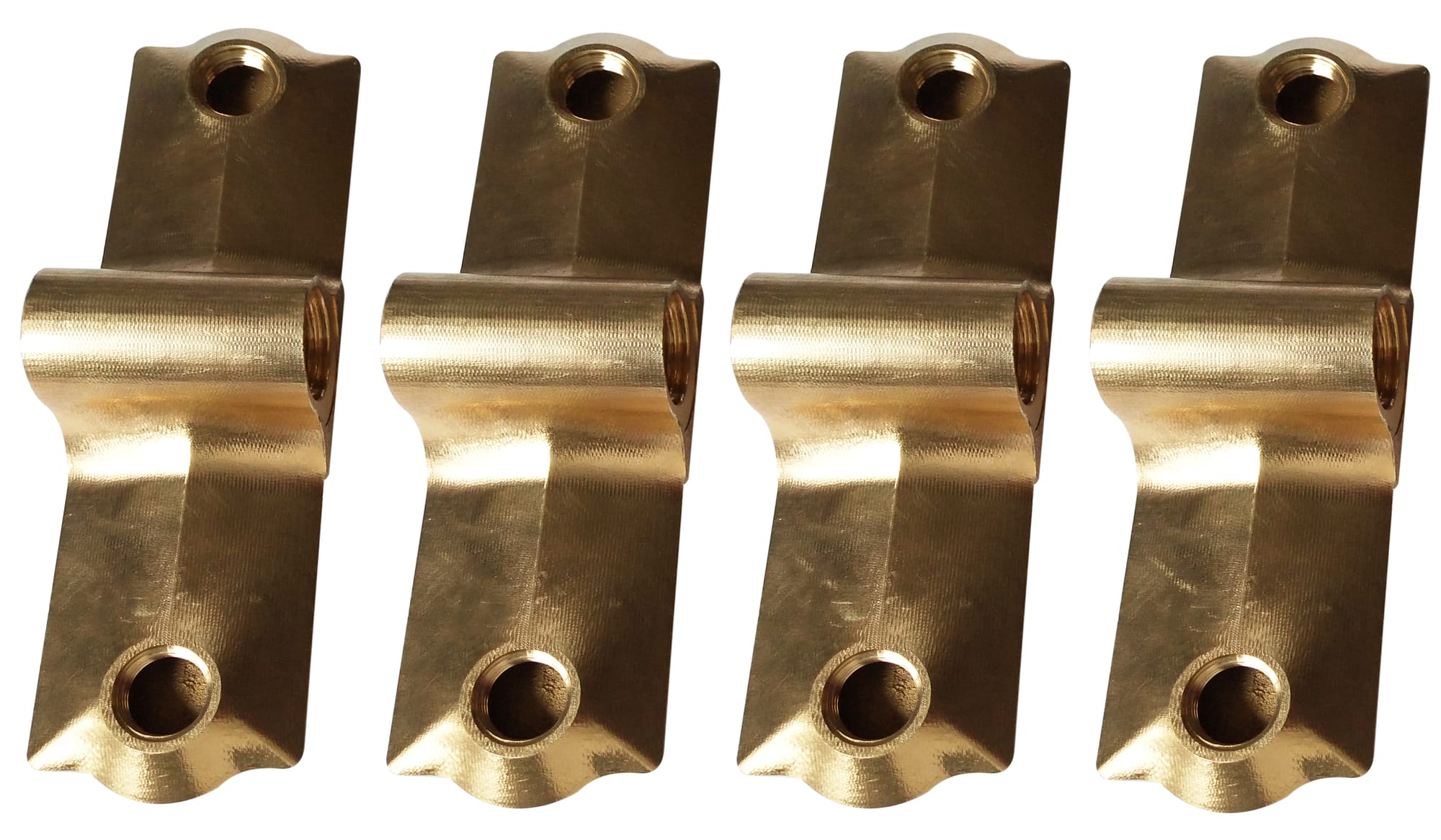

Here are some samples processed by our faucet making CNC machines for your reference.